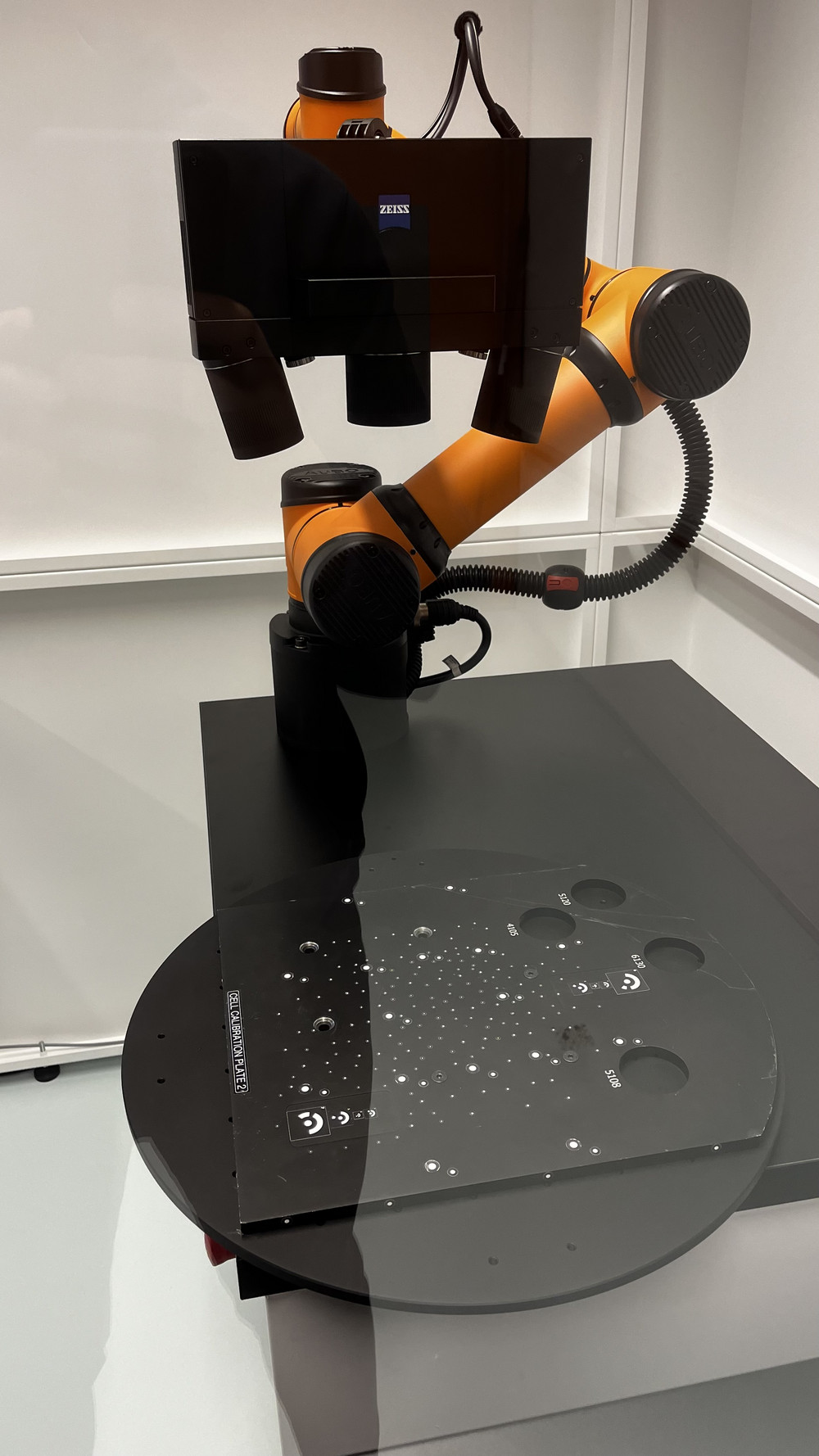

The ScanCobot from ZEISS 3D Automation has recently become part of the research paper and forms the heart of the new "Production Measurement Systems" research facility

The Zittau/Görlitz University of Applied Sciences (HSZG) is stepping up its activities in the CircProMet project - sustainable production measurement technology for disassembly processes with modern technology: The ScanCobot from ZEISS 3D Automation has recently become part of the research paper and forms the heart of the new "Production Measurement Systems" research facility.

CircProMet aims to develop an integrated optical 3D measurement system that can be used in both manual and automated dismantling processes in the Green Circular Economy (CircEcon ) large-scale research cluster. To this end, a research infrastructure is being created that combines the following components::

A powerful sensor head for precise 3D detection of components,

ScanCobot with robotic turntable module for flexible measuring tasks,

specialized software and high-performance hardware for processing large volumes of data.

The focus is on cyber-physical systems (CPS) with integrated production measurement technology and artificial intelligence (AI).

These technologies enable:

The aim is to achieve an innovative and highly efficient dismantling process that contributes directly to the goals of CircEcon.

The interdisciplinary cooperation between the Faculty of Mechanical Engineering and the Institute of Process Engineering, Process Automation and Production Metrology (IPM) enables developments from research to be transferred directly to regional companies. CircProMet thus makes an active contribution to structural change in Upper Lusatia and at the same time strengthens the position of the HSZG in the fields of production measurement technology and process automation.

The integration of the ScanCobot is an important step on the way to innovative, highly efficient and sustainable dismantling systems.